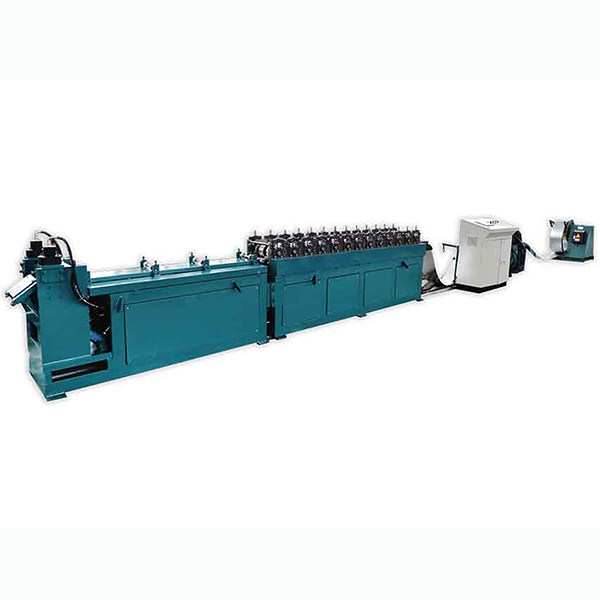

Fire Damper Making Machine

Fire damper manufacture machines are widely used in constructional engineering field to manufacture products for ventilating, air-conditioning and fire extinguishing system. By mass-producing dampers, the production is highly raised. The schedule of the project is ensured.

As the high cost, complicated technique, demanding to the workers and low yield rate of the welding type fire damper frame, Comifo started researching and developing the new fastening type fire damper frame since 2006. Comifo adopts modularized design for the damper manufacture machines, include of Damper Frame Manufacture Auto Line, Damper Blade Manufacture Auto Line, Damper Assemble Hydraulic Fastening Table, Dividing & Supporting Plate manufacture Auto Line, Spring Plate manufacture Auto line and etc. As different customer has different demand on damper manufacturing, different configured machines are recommended accordingly.

Fire damper making machine series

The Advantage of Comifo fire damper making machine

Comifo damper manufacture lines are configured by PLC, servo motor and touch screen industrial computer. It’s easy to operate. And also, the welding processing and painting are unnecessary to assemble a damper. To operate the machines, only several people are required. This saves labor cost very much, and the productivity is highly raised. Comifo offers total solution of damper manufacturing for customer base on our machines. The fire dampers which are manufactured by our machine are also meeting the requirements of CCC standard. If customers use Comifo Damper Frame Making Machine to manufacture dampers, we would offer our experience to help customers to apply the CCC certificate.

Maintenance is of great importance

To prolong life-span, a good maintenance for machines is very important. Considering of the machines service condition, the fire damper frame machine will be in working, being cared and maintained in most of time. During the construction process, the processing and use of fire damper equipment usually meets the requirements of large engineering, heavy tasks, high investment, tight schedule, and strong seasonal characteristics. According to the common fault analysis, 56% of the fire damper equipment is based on the problem caused by the loss of maintenance, 38% is the regular maintenance error, 6% is caused by the operation error, so the daily maintenance and anti-rust treatment of the fire damper equipment is necessary to ensure correct operation, which can effectively avoid the failure of fire valve equipment and the cost of secondary purchase.