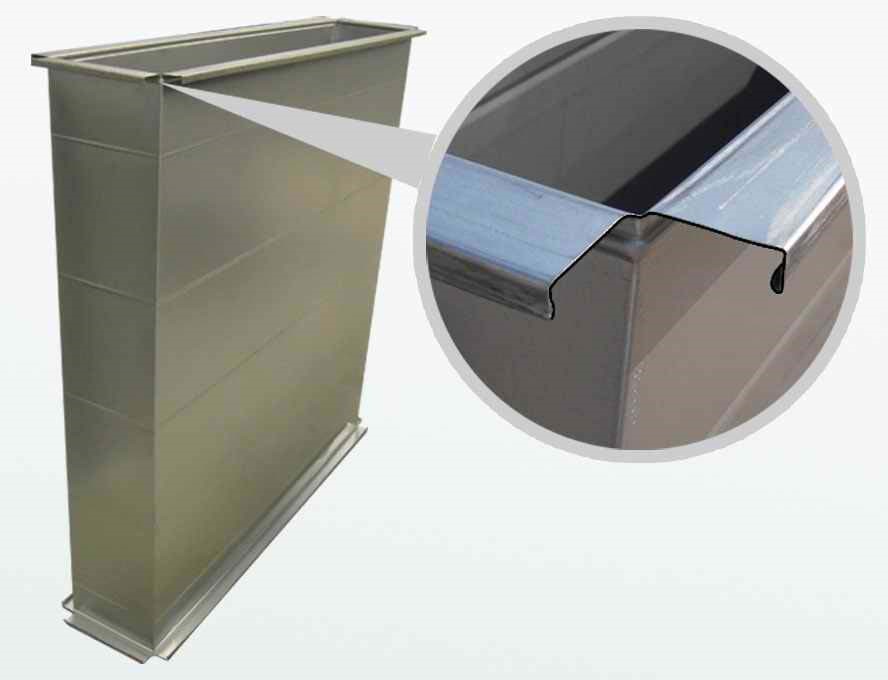

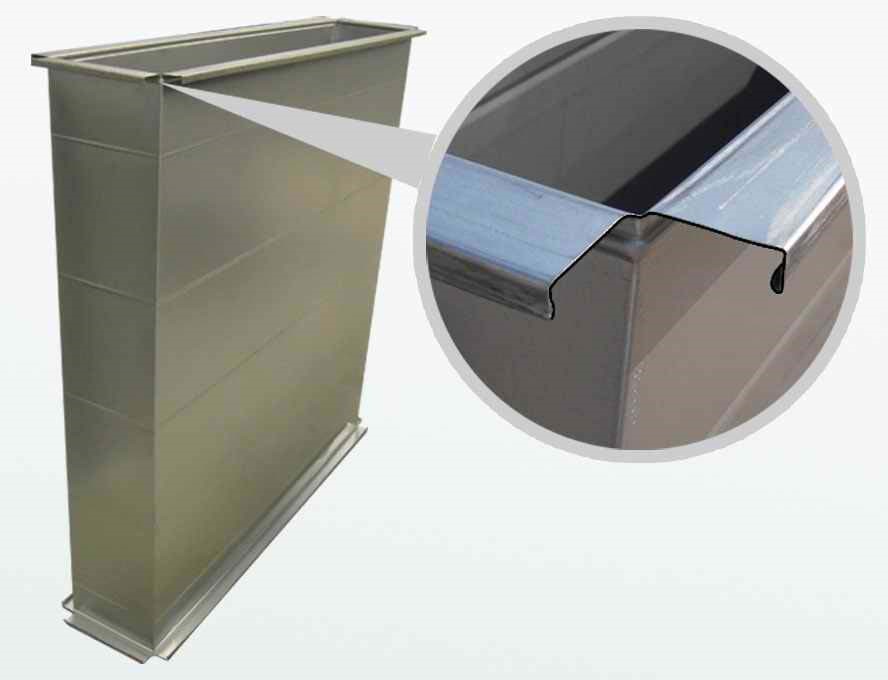

Galvanized duct manufacturing shall not damage the steel galvanized protective layer, galvanized air duct sheet metal plate should be used to take a single bite, usually speaking, for the circular duct closed and slit with a single bite mouth, elbow The horizontal seam adopts a vertical bite, while a joint corner bite is used for a rectangular duct.

Galvanized duct for the production of dimensions outside the length of whichever is for the size of the circular galvanized duct diameter to prevail. In addition, production of galvanized air duct using cutting board cutting, folding machine folding, biting mouth bite mouth, local manual.

For the galvanized duct, its production is a certain standard, that is to say, we must strictly in accordance with the rules of production to produce the most valuable application of galvanized duct, let's look at the relevant rules:

Rule one: What we need to understand is that we should not damage the galvanized steel sheet when making galvanized air duct.

Rule two: Galvanized air duct board should be used to fight a single bite, usually speaking, for the circular duct closed and sew with a single bite mouth, the horizontal bite bend elbow mouth, and for the rectangular duct Corner seam angle joint with the mouth.

Rule three: Under normal circumstances, the production of rectangular duct outside the size of whichever is longer, the diameter of the circular duct to the outside diameter. In addition, the production of galvanized duct cutting using shears, folding machine folding, biting mouth biting machine, the local use of hand.

Galvanized duct flange processing need to pay attention to what the problem?

1. Processing must be in accordance with the rules of the drawings together with the series of norms flange bolt holes used punching and die from the punching.

2. Galvanized duct flange molding welding must use a dedicated mold for positioning welding In order to ensure the same specifications of the duct flange interchangeability.

3. Galvanized duct flange material must be approved by the contractor, no rust, crust or pitting.

4. Flange welding seam roughness of not more than 0.5mm rivet hole distance of not more than 100mm, screw hole distance of not more than 120mm, and the pitch should be accurate, and have interchangeability.

5. Processing Galvanized duct flange generated welding slag, welding spatter, rust should be thoroughly cleaned.

Guangzhou Kang Mei Feng is a professional duct zipper machine manufacturers, producing automatic duct production line, safe, efficient and stable.