- Email: linhailan@comifo.com.cn

- Tel: +86-20-89817565

-

EN/ CN

Advantage

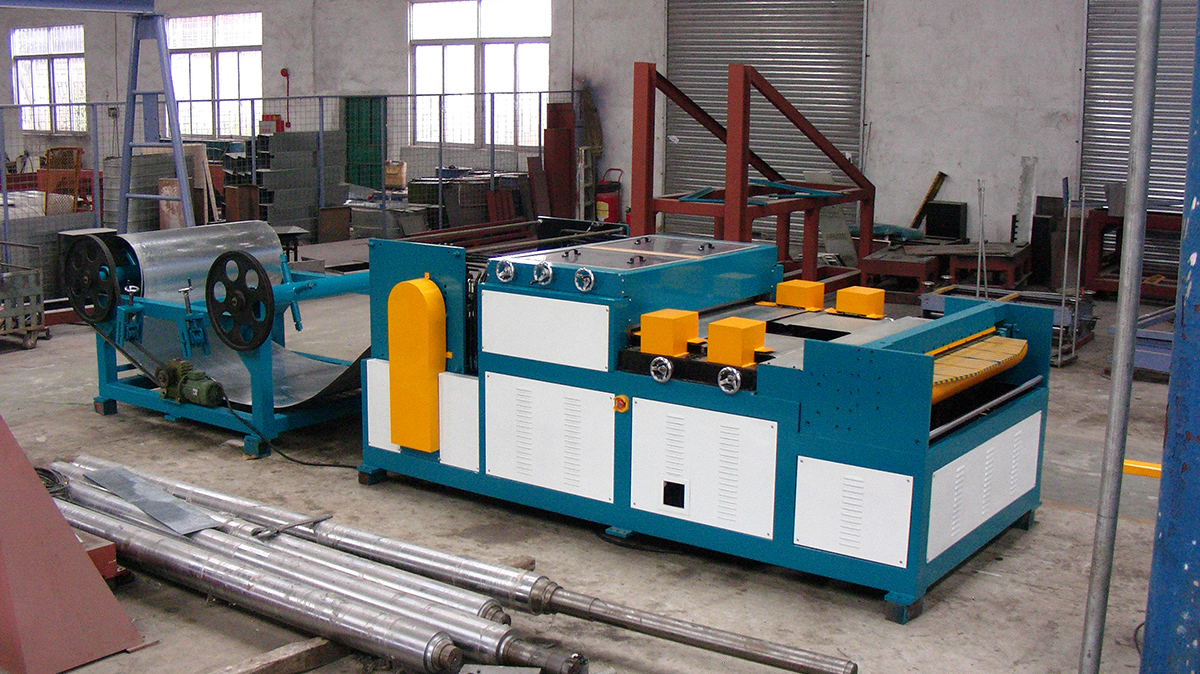

WITH 20 YEARS OF MACHINERY MANUFACTURE EXPERIENCE

DUCT MACHINE HAS BEEN SELLING TO MORE THAN 128 COUNTRIES AND AREAS

WITH 140,000㎡ FACTORY PRODUCTION AREA

WITH 24 PRODUCT PATENTS

Factory

contact us

DAMS Incorporated

We provide customers with quality products and provide high-quality services

If you would like to leave us a comment please go to